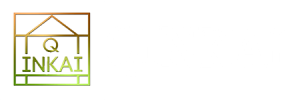

Qinkai Perforated Cable Tray with Good ventilation effect and cost-effective

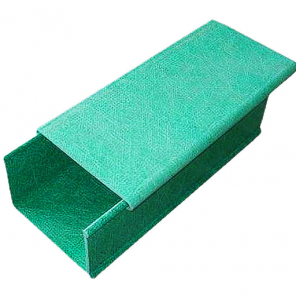

Perforated Cable tray systems are options to wire ways and electrical conductor, which completely enclose wires.

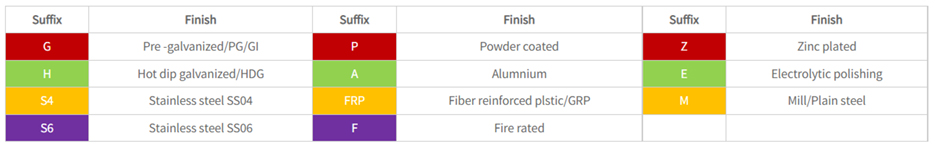

Most cable tray systems are built from a corrosion-resistant metal (low-carbon steel, stainless steel or an aluminum alloy) or from metal with a corrosion-resistant coating (zinc or epoxy).

The choice of metal for any particular connection depends on the connection environment (corrosion and electrical plans) and cost.

If you have list, please send your inqiury to us

Application

Perforated cable trays are capable of maintaining all types of cabling, such as:

1. High voltage wire.

2. Power frequency cable.

3. Power cable.

4. Telecommunication line.

Benefits

Lower cost: One of the advantages of using perforated cable tray is that it costs much less than other protective cabling systems on the inventory floor.

Support: The perforated cable tray can be checked immediately, because wires can enter and exit the perforated cable tray at any operation point, so the cable development is easy.

Safety: Regular housework is important for safety, because perforated cable trays are usually set in places that are difficult to move.

Parameter

|

Oerdering Code |

W |

H |

L |

|

|

QK1(the size can modified according to project requriements) |

QK1-50-50 |

50MM |

50MM |

1-12M |

|

QK1-100-50 |

100MM |

50MM |

1-12M |

|

|

QK1-150-50 |

150MM |

50MM |

1-12M |

|

|

QK1-200-50 |

200MM |

50MM |

1-12M |

|

|

QK1-250-50 |

250MM |

50MM |

1-12M |

|

|

QK1-300-50 |

300MM |

50MM |

1-12M |

|

|

QK1-400-50 |

400MM |

50MM |

1-12M |

|

|

QK1-450-50 |

450MM |

50MM |

1-12M |

|

|

QK1-500-50 |

500MM |

50MM |

1-12M |

|

|

QK1-600-50 |

600MM |

50MM |

1-12M |

|

|

QK1-75-75 |

75MM |

75MM |

1-12M |

|

|

QK1-100-75 |

100MM |

75MM |

1-12M |

|

|

QK1-150-75 |

150MM |

75MM |

1-12M |

|

|

QK1-200-75 |

200MM |

75MM |

1-12M |

|

|

QK1-250-75 |

250MM |

75MM |

1-12M |

|

|

QK1-300-75 |

300MM |

75MM |

1-12M |

|

|

QK1-400-75 |

400MM |

75MM |

1-12M |

|

|

QK1-450-75 |

450MM |

75MM |

1-12M |

|

|

QK1-500-75 |

500MM |

75MM |

1-12M |

|

|

QK1-600-75 |

600MM |

75MM |

1-12M |

|

|

QK1-100-100 |

100MM |

100MM |

1-12M |

|

|

QK1-150-100 |

150MM |

100MM |

1-12M |

|

|

QK1-200-100 |

200MM |

100MM |

1-12M |

|

|

QK1-250-100 |

250MM |

100MM |

1-12M |

|

|

QK1-300-100 |

300MM |

100MM |

1-12M |

|

|

QK1-400-100 |

400MM |

100MM |

1-12M |

|

|

QK1-450-100 |

450MM |

100MM |

1-12M |

|

|

QK1-500-100 |

500MM |

100MM |

1-12M |

|

|

QK1-600-100 |

600MM |

100MM |

1-12M |

|

If you need know more about perforated cable tray. Welcome to visit our factory or send us enquiry.

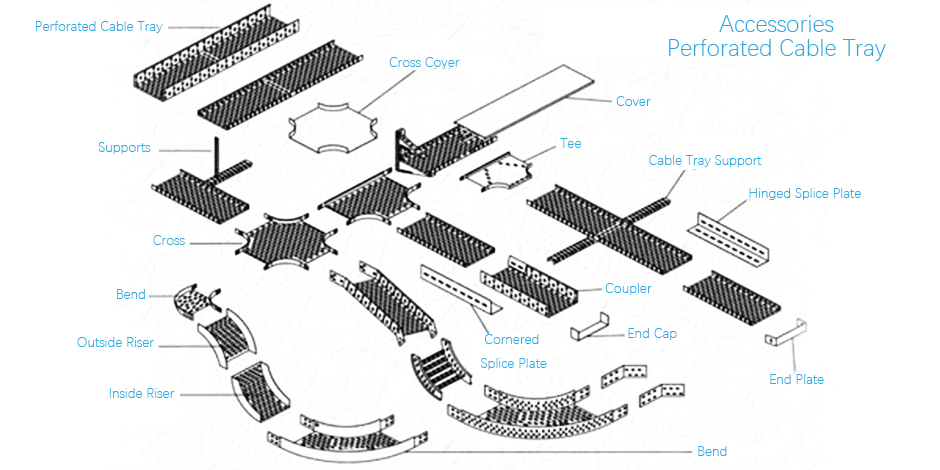

Detail Image

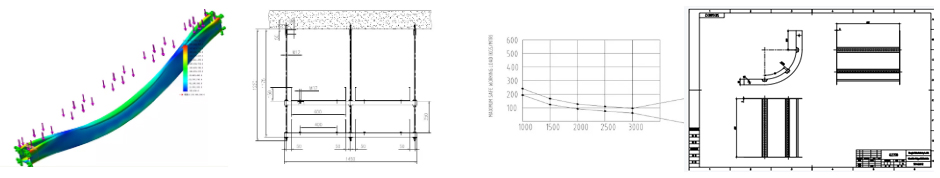

Perforated Cable Tray Inspection

Perforated Cable Tray One Way Package

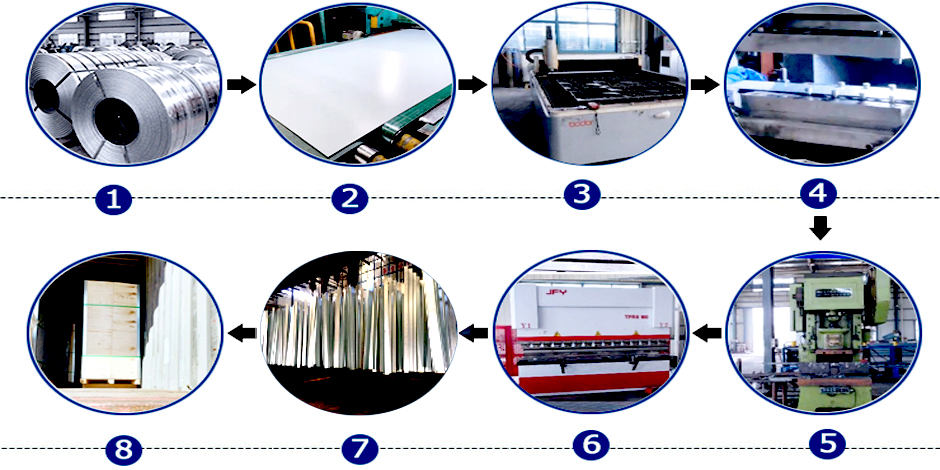

Perforated Cable Tray Process Flow

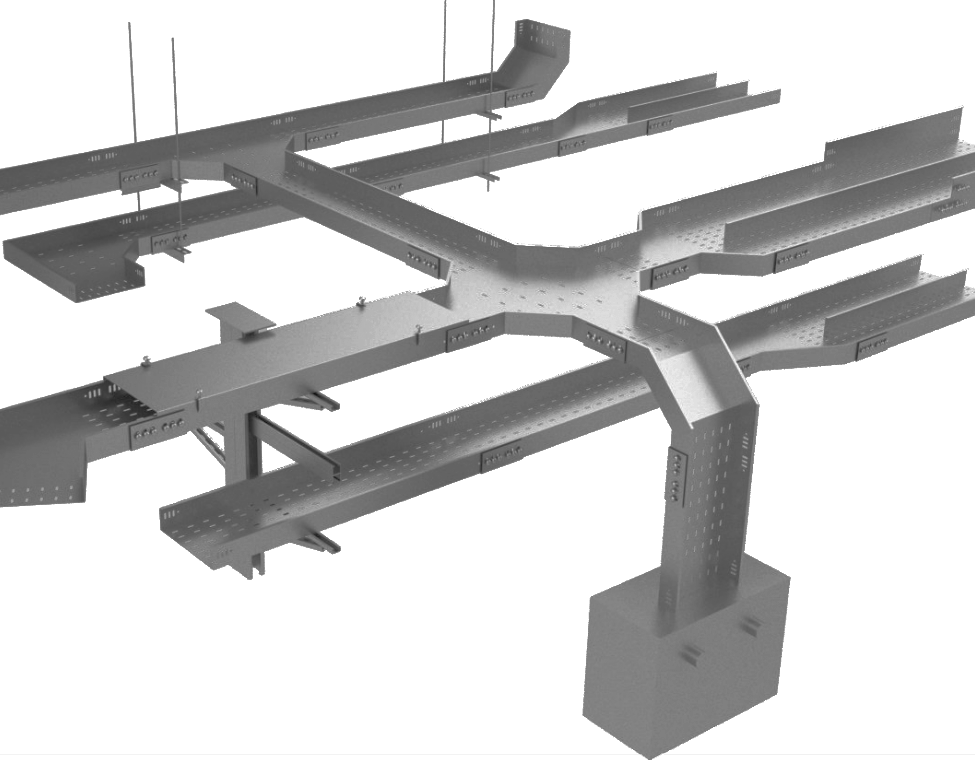

Perforated Cable Tray Project